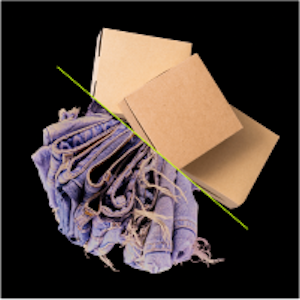

Saving climate-critical forests by scaling low impact NEXT GEN alternatives - made from waste textiles and agricultural residues. NEXT GEN fibres have 95% to 130% less GHG emissions, 88% to 100% less land-use impacts and 5x lower impact on biodiversity and threatened species.